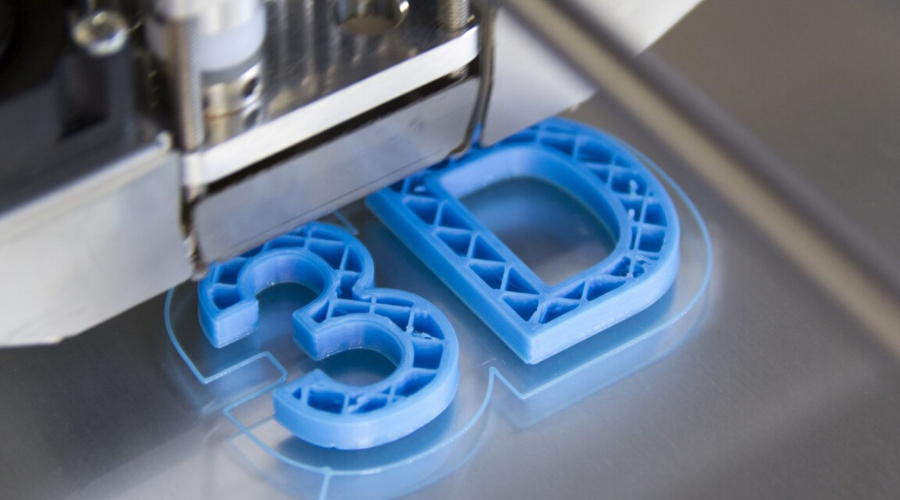

Incredible Benefits of 3d Printing

Product manufacturing is accomplished in three varied ways. There is traditional printing, subtractive manufacturing and injection molding. In the subtractive method as the name suggests, each layer is subtracted one after the other till they receive their desired product. In the injection moulding method, they manufacture products by positioning heated material in the form of moulds. Now we have 3D printing or additive manufacturing singapore which is a manufacturing process. It utilizes computer files in order to manufacture 3D products and as the name suggests it is done by adding layers one after the other, hence the name additive printing.

Owing to the numerous benefits 3D printing offers, it has created quite a stir in the manufacturing Arena. because of these benefits it is considered over the conventional printing methods such as the injection molding and the subtractive printing methods.

Speed

Before the 3D printing method was introduced, the production of a specific product with the help of a prototype took many days for preparation. when there were any changes that they had to make, it would take more time for it and then there would be the shipping time also. all in all, it took too much time before it reached the final stage.

3D printing utilizes rapid prototyping which makes designing, testing, manufacturing and all the other processes of the manufacturing process superfast. even when there have to be changes made, it does not result in loss of time. 3D printing has aced it when it comes to speed.

Cost

It is the most cost effective process when it comes to manufacturing and unlike the conventional printing methods which use expensive and heavy machinery. They also need trained technicians in order to operate the machines. Contrary to this, 3D printing needs only limited machinery. There is also limited wastage of any material used for manufacturing because of this process and material is not subtracted in product manufacturing.

Flexibility

In the conventional printing methods when products are manufactured or when changes are made to a specific design. It always requires a new mould. It has to be prepared from scratch. Nevertheless the 3D printing method has a printer and it makes some products that fit into any capacity. When changes are to be made the same is fed to the computer software and the change is made to the design.